Paper

Gloss, Silk, Matte, Velvet, Dull, and Satin

Smooth, Super Smooth, Vellum, and Wove

Crest, Eggshell, Felt, Laid, Linen, Stipple, and more

Coated, Uncoated, WTC, Specialty, Copy, and more

C1S, C2S, Cast Coated, CCNB and more

Whites, Neutrals, and Colors

20lb – 100lb Text, 60lb – 130lb Cover

Uncoated, Neutrals & Brights, Recycled, and more

Coated, Uncoated, WTC, Specialty, Copy paper, and more

FSC Certified, SFI Certified, Post-Consumer Waste, Recycled Fiber, and more

Synthetic Papers, Die Cut and Dimensional Products, Carbonless Paper, Pressure Sensitive Adhesive

Calculate the amount of paper necessary to print a magazine, catalog, or brochure.

Converting

Maximize production efficiencies with Lindenmeyr Munroe’s converting program. Our converting facilities are equipped with guillotine trimmers, precision cutters and cartonizing lines, benefiting our customers by cutting paper, packaging, and wide format products to project specifications.

Maximize product

efficiencies

Cost savings /

yield advantage

Natural resource

efficiency

Waste reduction

by as much as 30%

TOOLS & RESOURCES

|

|

|||||||||||

|

|

||||||||||||

|

Select Measurement US Metric |

||||||||||||

|

|

||||||||||||

|

|

||||||||||||

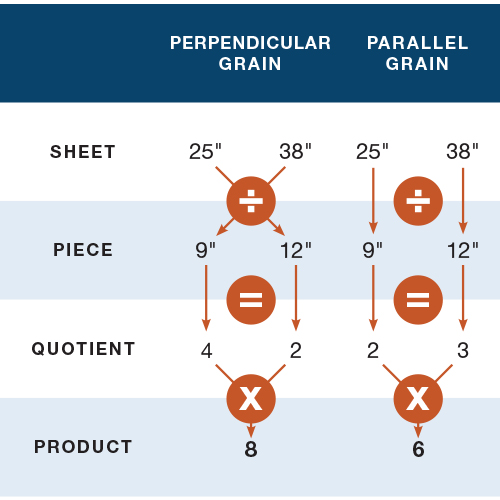

CALCULATE PIECES PER SHEET

Use this simple diagram to determine the highest yield when cutting down parent sheets.

For a perpendicular grain cut, take the dimensions of your parent size sheet and underneath that take the dimensions of the sheet size desired and divide those numbers diagonally. (See image below). Multiply those 2 numbers together to give you your final yield.

For a parallel grain cut, take the dimensions of your parent size sheet and underneath that take the dimensions of the sheet size desired and divide those numbers vertically. (See image below). Multiply those 2 numbers together to give you your final yield.

Whichever final yield is larger determines how to best cut parent sheets for the highest yield.

DETERMINE GRAIN DIRECTION

One or more of the following five tests will determine the direction of grain:

- Cut a sample about 2 inches square from the sheet marking its original position in the sheet. Wet it. As it dries it will curl. The grain is the direction of the curl.

- Moisten two right-angle edges of the sheet, and press between the fingers. As the sheet dries, the edge across the grain will be wavy; with the grain, straight.

- Tear the sheet in two directions. It tears straighter and cleaner with the grain.

- Fold the sheet in two directions. It folds easier and smoother with the grain.

- If paper has a laid finish, the grain is usually parallel to the chain marks (widely spaced lines). This is not a conclusive test because paper is sometimes made with the chain marks running across the grain.

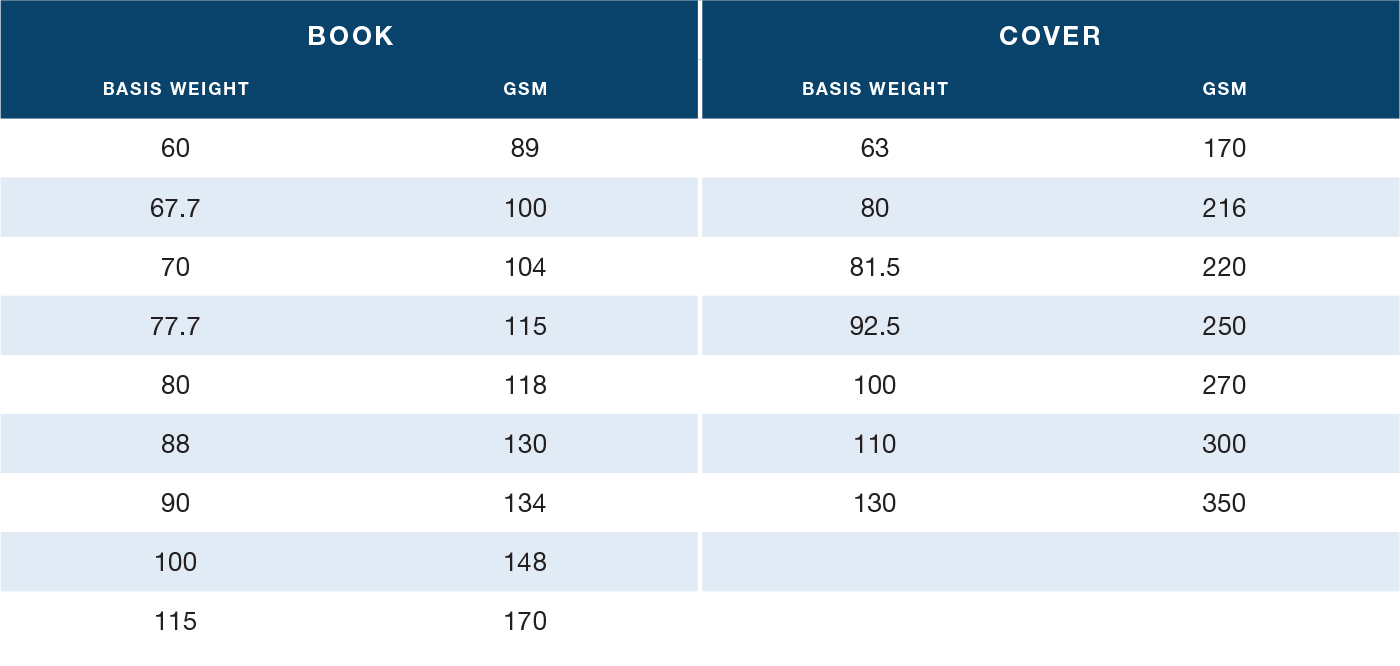

CONVERT BASIS WEIGHT TO METRIC

The schedule below allows you to find the M weight (weight of 1000 sheets) of any special size sheet. The length x width of the sheets gives you the number of square inches in the special size sheet. If you then multiply this figure times the Constant Factor (weight of 1000 sheets one inch square) you will get the M weight of that special size.

Example: You estimate you need a special sheet size of 27 x 39 Basis 70 white #3 Offset. Multiplying 27 x 39 you get 1053 sq. inches. Under “Book Paper” you get a constant factor figure of .1474 equals 155.2122 or 155 lbs. per 1 M sheets 27 x 39.